BIOCOM

CASCADE PRINCIPLE UP TO 400 KW

INDUSTRIAL STEP GRATE TECHNOLOGY

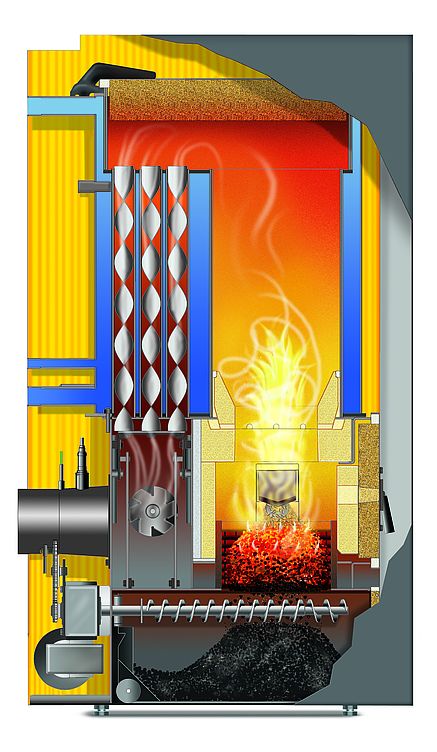

Biocom heating systems, with industrial step grate technology, combine maximum economy with minimum emissions. These boilers can operate with wood pellets of varying quality.

Pellet/- Hybrid Konfigurator

FINDEN SIE EINFACH UND SCHNELL IHR PASSENDES HEIZSYSTEM

Konfigurator starten

Benefits

Highly efficient combustion

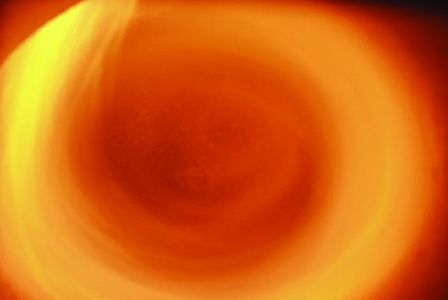

The wood pellets are gasified on the industrial step grate, where primary air is supplied at an ember bed temperature of around 800 °C. The amount of combustion air and fuel charge is regulated by means of a lambda probe, so that the system achieves a level of efficiency of up to 94 %. With the aid of secondary air, the generated combustion gases are cleanly and efficiently converted into energy in a large rotating combustion zone.

Cleaning has never been easier

Conventional pellet heating systems still require regular cleaning. The Biocom system, on the other hand, cleans the heat exchanger and step grate (with the exception of a general clean-up) automatically. Large ash boxes reduce the remaining effort to a minimum.

perfect storage

Guntamatic storage systems operate with suction discharge and screw conveyor dosing, resulting in outstanding operational reliability and durability. When the fuel is completely used up, there is no need for the annual storage room cleaning. Depending on preference, a high grade steel/mesh hopper or sloping floor storage room with discharge screw conveyor are available.

pioneering, straightforward operating concept:

Fully automatic control of appliance and storage room functions, as well as regulation of the ambient climate utilising the most advanced control technology. Individual adjustments can be made easily via the clear touchscreen controller, possibly via a room control station or a smartphone app.

DURABLE QUALITY

In order to ensure that our appliances meet our high quality aspirations and those of our demanding customers, we manufacture them completely and exclusively using the best possible materials in our ultra-modern Austrian factory.

Highest level

of convenience

It's all a matter of technology

Industrial step grate technology

BIOCOM systems operate with a self-cleaning step grate which is generally only found in larger plants. This enables the ember bed height and boiler output to be adjusted in line with demand and fuel, without risking slag forming inside the boiler. The moving step grate keeps the primary air slots clean, ensures optimum combustion and also that ash is correctly discharged.

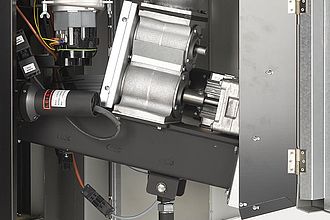

High grade components

In order to prevent unintentional surprises, BIOCOM boilers are made exclusively using the highest grade components. The robust version of the vacuum system and screw conveyor discharge, the reliable motors and gear units and the resilient silicon combustion chamber with step grate technology are but a few examples of this.

BOX

BOX containers of various sizes are available to suit the dimensions of each available storage room. The steel floor and fabric design is extremely capacious and also allows the container to be emptied completely, thereby reducing the cleaning effort. An screw conveyor-dosing vacuum discharge guarantees highly reliable operation.

FLEX

Guntamatic Flex discharge units are suitable for particularly large, intensively used, storage facilities.

The discharge screw conveyor of the vacuum discharge system has been designed for efficiency and a long service life. It offers a highly reliable operation as well as low cleaning effort,

and discharge from stores with sloping floors. Where the sloping floors are made on site, this is also a particularly affordable solution.

AUTOMATICALLY HEATING WITH ECONOMY

Ecological and economical heating convenience

- Self-cleaning industrial step grate for adjusting the ember bed size and boiler output without generating slag

- Clean primary air slots and optimum combustion through moving step grate technology

- Up to 95 % efficiency

- Self-cleaning tube bundle heat exchanger ensures long operating times without maintenance or cleaning measures

- Automatic adjustment of the fuel charge, grate speed and air intake

- Suitable for pellets class ENPlus A1 and ENPlus A2

- Ash screw conveyor and moveable ash box or fully automatic vacuum ash discharge into a 200 litre drum (option) for the highest cleaning convenience

- Well thought-out and user friendly interface with touchscreen

- Control by mobile (option)

- High grade components for maximum operational reliability

- Multi-stage safety concept through stoker unit controlled by lambda probes, protects against back burning and unpleasant surprises

- First class spare parts service from our own production

- Secure cascade operation prevents total downtime

- Modular pellet discharge concept, suitable for almost every situation

- Robust, gentle screw conveyor system for high operational reliability

- Minimum power consumption thanks to energy efficient discharge

- Extremely robust pellet discharge screw conveyor with sprung arm agitator

Specification

Tabelle zum scrollen

Tabelle zum scrollen

TYPE | BIOCOM 50 | BIOCOM 75 | BIOCOM 100 | |

|---|---|---|---|---|

Up to four individual boilers can be linked to form a single cascade. | ||||

Fuel | Pellets ENplus A1/A2 | Pellets ENplus A1/A2 | Pellets ENplus A1/A2 | EU standard EN 14961-2 |

Boiler output | 13,3 - 49 | 22,5 - 75 | 26,2 - 99/101 | kW |

Required chimney draught | 0.15 | 0.15 | 0.15 | mbar |

Water content | 147 | 256 | 256 | Litre |

Ash box – "grate" | 60 | 80 | 80 | Litre |

System width | 1474 | 1774 | 1774 | mm |

Total weight (without stoker unit) | 585 | 865 | 865 | kg |

Safety heat exchanger | yes | yes | yes |

|

Power supply | 230 V / 13 A | 230 V / 13 A | 230 V / 13 A |

|

Test report

Summary of test assessments:

"extremely high efficiency thanks to industrial step grate technology (even with the lower output range); particularly clean and efficient combustion through large rotating combustion zone<br/> ; high quality components for a long service life; …”

- Tested for cleanest combustion and particularly high efficiency to EN 303-5 during 2005 and 2008 by the BLT Wieselburg and in 2006 by the TÜV BAYERN SZA

- Tested for mechanical robustness (under pressure) by the TÜV SÜD SZA

- Tested for fire safety by the IBS Linz

- Tested in accordance with the strict requirements of the European Machine and Plant Safety (CE)

- Tested for electrical safety by Ziviltechnik Stöp

- Assessment of risk analysis and CE certification by HET engineers

Awarded the Austrian Innovation Prize 2005

Awarded the Austrian Environmental seal ZU 37