BIOSTAR PELLET HEATING SYSTEM

12/15/23 KW

Modulating pellet combustion

Biostar systems feature a unique concept with the highest efficiency and maximum modulation ability. This enables you to operate with extreme efficiency and optimum convenience, even in the low temperature range, keeping your system absolutely futureproof.

Pellet/- Hybrid Konfigurator

FINDEN SIE EINFACH UND SCHNELL IHR PASSENDES HEIZSYSTEM

Konfigurator starten

Benefits

clean combustion and efficient

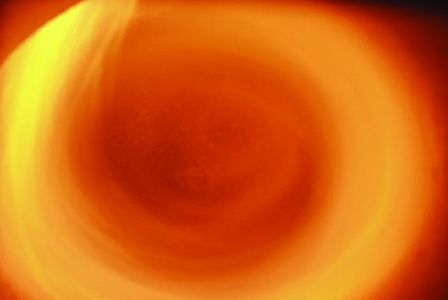

Our BIOSTAR low temperature boilers are amongst the most innovative pellet heating systems on the market. The flexible combustion concept with variable ember bed height, plus intelligent lambda control, safeguards maximum heating efficiency and compliance with the most stringent emission standards.

affordable installation and operation

Output and boiler water temperature are matched to the actual demand of the building in a unique fashion. As a result, no buffer cylinder is required. Existing oil boilers can be replaced with minimal effort and cost. In addition, the resulting high seasonal efficiency factor ensures very low consumption.

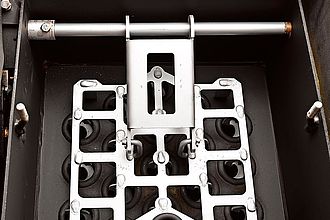

Cleaning has never been easier

Conventional pellet heating systems still require regular cleaning. The Biostar system, on the other hand, cleans the combustion chamber, heat exchanger and grate area (with the exception of general cleaning) automatically. A large ash box reduces the remaining effort to a minimum.

perfect storage

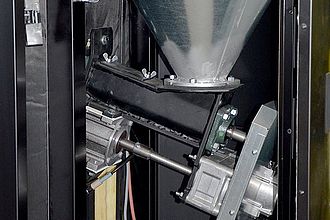

Guntamatic storage systems operate with suction discharge and screw conveyor dosing, resulting in outstanding operational reliability and durability. When the fuel is completely used up, there is no need for the annual storage room cleaning. Depending on preference, a high grade steel/mesh hopper or sloping floor storage room with discharge screw conveyor are available.

pioneering, straightforward operating concept:

Fully automatic control of appliance and storage room functions, as well as regulation of the ambient climate utilising the most advanced control technology. Individual adjustments can be made easily via the clear touchscreen controller, possibly via a room control station or a smartphone app.

low maintenance costs, long service life

Advanced technology, robust appliance design and careful manufacture are the cornerstones of success for BIOSTAR systems. They require little maintenance and are built for an exceptionally long service life. Throughout their life cycle, these appliances deliver environmentally sound heating to their owners with the utmost reliability.

Highest level

of convenience

It's all a matter of technology

BOX

BOX containers of various sizes are available to suit the dimensions of each available storage room. The steel floor and fabric design is extremely capacious and also allows the container to be emptied completely, thereby reducing the cleaning effort. An screw conveyor-dosing vacuum discharge guarantees highly reliable operation.

FLEX

Guntamatic Flex discharge units are suitable for particularly large, intensively used, storage facilities.

The discharge screw conveyor of the vacuum discharge system has been designed for efficiency and a long service life. It offers a highly reliable operation as well as low cleaning effort,

and discharge from stores with sloping floors. Where the sloping floors are made on site, this is also a particularly affordable solution.

HEATING RESPONSIBLY

- More than 15 years of development have gone into one of the best proven low temperature pellet boilers in Europe

- Variable output control – from 3 to 23 kW

- Setback down to 38 °C without loss of efficiency; no buffer cylinder required

- Economical and ecological replacement for old oil heating systems

- May be combined with fireplace inserts or stoves, as well as almost any heat source (e.g. BIOSMART auxiliary log boilers)

- Adaptable pellet storage in a separate store or special pellet container

- Unique safety concept and highest operational reliability

- Variable ember bed height and intelligent control for maximum heating efficiency and compliance with the most stringent emission standards

- Low temperature heat exchanger and lambda probe control for optimum degassing at 800 – 1000 °C

- Convenient control by means of a touchscreen interface or a room device, smartphone or PC (optional)

- Advanced technology, low/wearing appliance design and careful production for optimum durability

- First class spare parts service from our own production

- Induction fan, cleaning motor and drive motors are all made for low power consumption

- Current version can be updated

Specification

Tabelle zum scrollen

Tabelle zum scrollen

TYPE | BIOSTAR 12 | BIOSTAR 15 | BIOSTAR 23 | |

Fuel Energy efficiency class Rated output | Pellets ENplus A1 A+ 15 | Pellets ENplus A1 A+ 15 | Pellets ENplus A1 A+ 23 | EU standard EN 14961-2 kW Litre |

** Weight excl. Flex discharge

Test report

Summary of test assessments:

"direct replacement of oil heating systems (without installation of a buffer cylinder) made possible by positive modulation ability; particularly frugal and clean thanks to high temperature combustion technology; low maintenance and durable design with high grade components; observe room height, ..."

- Tested for cleanest combustion and particularly high efficiency to EN 303-5 during 1999, 2002 and 2008 by the BLT Wieselburg

- Tested for mechanical robustness (under pressure) by the TÜV SÜD SZA

- Tested for fire safety by the IBS Linz

- Tested in accordance with the strict requirements of the European Machine and Plant Safety (CE)

- Tested for electrical safety by Ziviltechnik Stöp

- Assessment of risk analysis and CE certification by HET engineers

Awarded the Austrian Innovation Prize 1999

Awarded the French Innovation Prize 2005

Awarded the Czech Innovation Prize 2009

Awarded the Austrian Environmental seal ZU 37